I've been working my "vintage" Waring 11-298 blender hard for the past 3 years since I received it at a garage sale for free (I refused to make an offer, and the lady just said I could have it).

However, one day I was blending a smoothie and the blade assembly came loose from the base of the pitcher. I noticed some unusual vibration, the blending action was not working like it should, and on top of that, the contents started leaking out the bottom. It was time to give this blender some maintenance.

First, using all the socket extensions available, I unscrewed the blade. Then, not pictured, unscrewing the bushing assembly with pliers.

It appeared that the gasket/o-ring/rubber washer seals had become fossilized over the past few decades, and started cracking. This would definitely be the source of problem.

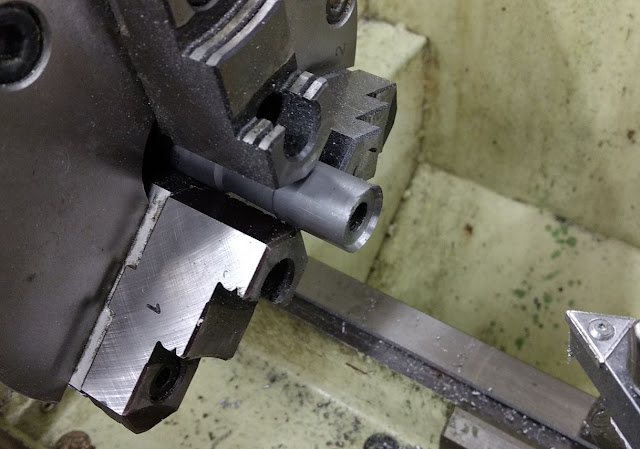

I wasn't able to find any replacement washers locally the exact size (1-1/4" outer diameter, 3/4" inner). I did find some with the correct outer diameter, but smaller inner diameter, so I decided to make a punch to open up the correct sized hole. Here I am turning the punch in the lathe from some scrap 3/4" material.

Then using the metal washer as a centering template, punching the new washers.

New washer successfully punched!

Then reassembling the bushing assembly with the new washers. The nut here is left-hand threaded, which seemed curious since the blade rotates counterclockwise from this direction. Visually, you would think the rotation of the blade would unscrew the bushing, but as vector dynamics would prove, the resistance from the material being blended its constantly pushing opposite the direction of rotation, thus making the seal tighter. This is the same principle for why bike pedals screw on in seemingly the wrong direction also.

I was still doubtful of this at the time, so I put thread locker on the threads here, which in retrospect, might've been a mistake since I'm now preventing the nut from tightening as the rubber washers flatten over time.

The other curious design feature which also seemed like a flaw, was the blade is secured to the shaft with just an acorn nut with no anti-rotation feature. Again, this would suggest the blending action would unscrew the blade, but by some magic, it stays on.

Anyways, I figured I might as well sharpen the blade while I had it removed. Using a Dremel sanding wheel here, taking care not to make the edge too pointy and weak. As it appeared, the original blade was actually ground with a slight flat on the end of the blades. I suppose people in the 1970's weren't into blending kale and celery yet, so they didn't need it so sharp.

Alright! let's test it out making some pomegranate walnut sauce!

Total success! I think the blade sharpening made a positive difference in blending efficiency too! By the way, this pomegranate walnut sauce is really good. I got the idea from a middle eastern restaurant. Mine consisted of just pomegranates, walnuts and a little bit of water.

(As a side note, humans have a natural affinity for foods like this that

have a 50-50 sugar-fat ratio because this is the same ratio as breast

milk.)

The blade assembly is rock solid better than before!

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.