First disassembling the thing. Wow! that's a lot of grease.

Using a punch to remove a bearing.

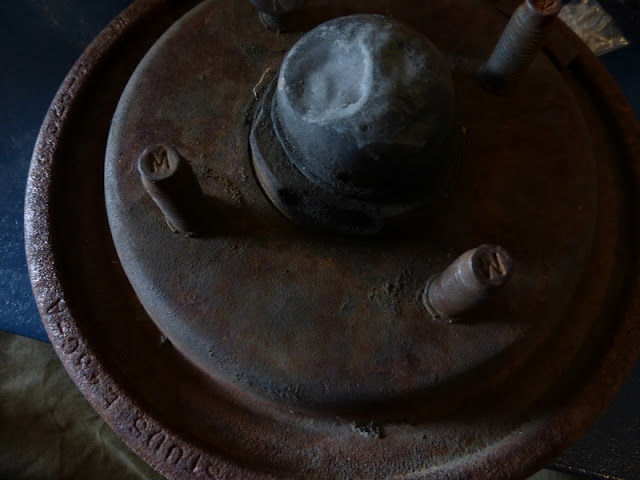

What it looked like after cleaning and removing the parts.

The bonus loot: two taper bearings, a cap, a nut, castle nut, toothed washer, cotter key, cap, etc.

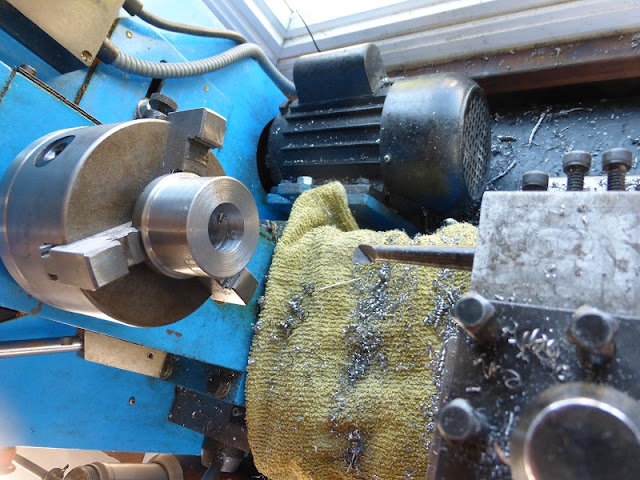

Now turning an adapter for the 7/8" tubing to insert into the base.

I decided this would be fancy, so I bought some stainless tubing so it wouldn't looks like that ugly chrome plated one I have... this is the equivalent of the church buying gold candlesticks because brass aren't good enough.

Tapping a 3/8" set screw hole in the adapter.

Then filing a flat on the 7/8 tubing.

Connected.

Now tapping some holes in the bottom to secure the adapter to the base.

Somehow, this was the only way I could hold the next piece in the lathe to turn the diameter to match that of the bearing I removed.

The scrap piece fit into where the bearing was.

Pretty clean.

Guess what color White's mic stand gets painted? Hey, that doesn't look like semi-gloss, more like snow powder, seems the paint was clogged at first...

The base pieces connected.

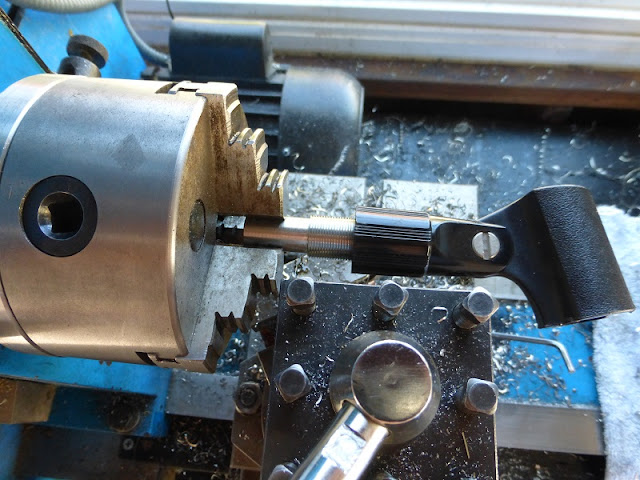

Now for the height adjustment, I decided to make a collet, first turning the diameter to fit into the 7/8" tubing.

Almost fit except for the weld seam inside the tubing.

Filing the seam.

Next before threading it, looking in the machinist's handbook to get the diameter dimension.

|

| Maurice, we need mo' rice! |

Checking the thread with a nut.

Then drilling and boring for the 5/8" tube.

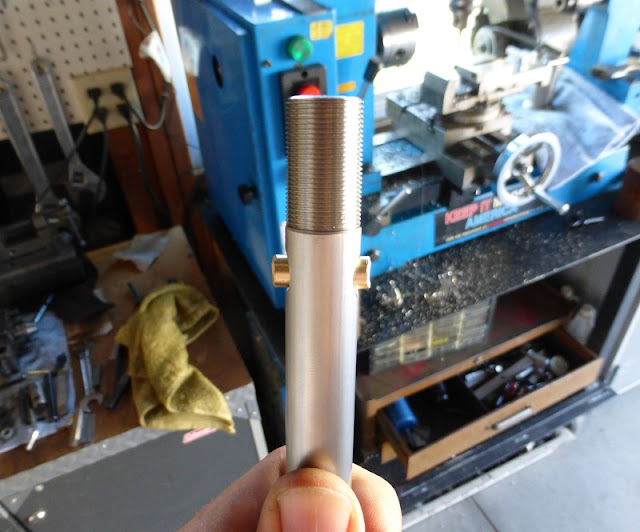

Then threading a 5/8"-27 thread for the microphone clip. I want to know the menace who decided that 27 threads per inch would be the standard for microphone stands.... it's not even a standard thread size, and several of the lathes I've encountered don't even have 27 as an option. But mine does!

Now instead of welding this stuff together, I decided to use a brass rivet.

Gives a much cleaner look too.

Then after flattening the ends, I figured I'd letter stamp an M & W on either side.

Mostly successful, though letter stamping a curved surface proved to be harder than expected.

With the rivet I accidentally made an "anti-falls-through-the-floor" mechanism. This picture shows the hacksawing I did to make the collet.

At first I thought I could make the locking mechanism by putting some O-rings in internal groove I turned into the collet and then using the 7/8 nut to tighten it, which proved to be a massive failure.

Then I remembered I have a camera tripod that has a smarter collet mechanism, so I borrowed the design. First tapering the top of the collet.

I figured I'd use the nut to connect the collet with the 7/8" tubing, so I bored out half of the thread to 7/8".

The part in the lathe is the new locknut which I threaded internally with the 7/8" thread. I decided it would be easier to make the taper a separate piece so I could thread the piece all the way through. The scrap piece used for the tapered part happened to be a failed oil burner design.

Turning the taper in the scrap piece.

Then cutting off the part I needed.

Facing the tapered piece.

The tapered piece fit into the locknut which goes over the collet which clamps the 5/8" tube and fits into the 7/8" tube which is held on with the 7/8" nut.... If any of that made any sense, it might make even less after this diagram:

As unnecessarily complicated this is, it actually worked. I don't have any way to powder coat the locknut at the moment, so I decided to just draw some symbols from the inside cover of All n All.

|

| The name is Jupiter!!!! |

I found some stick-on pads at a garage sale to protect the floor.

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.