Lesson 1 on how to read vernier calipers: 3.9"+.025"+.019"= 3.44" It seems like at every job I've had, they've been really impressed that I actually know how to read these (or because my vision is good enough to see that small!) It pays to use cheap $15 calipers! Besides, they're much harder to break than dial or digital ones, and just about as accurate as far as calipers are concerned.

Here's the rear hub. Note the extra axle length and the thread for the freewheel.

Aww shucks, this one turned out blurry, but you can kinda see the .025" difference. Actually, don't try to read it. I was told that welders develop poor vision not from the brightness, but by trying to focus on something that's too dark/ unclear to see through the lenses.

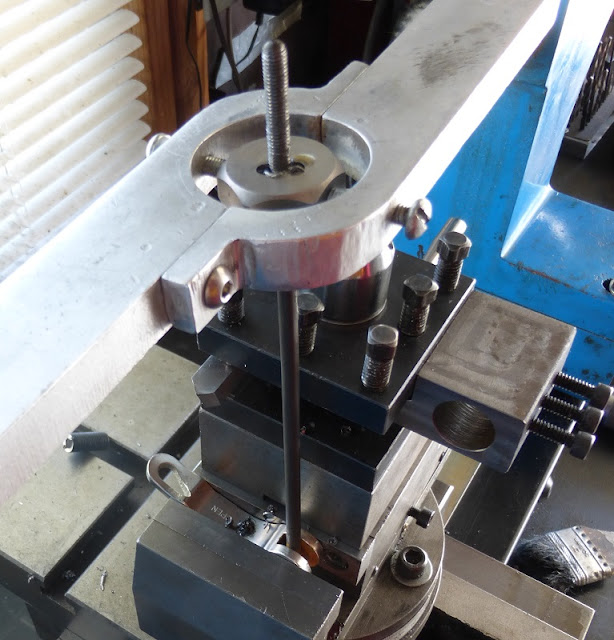

I took out the axle and put it in the lathe (after hacksawing most of the excess) and faced the end to length.

Then chamfering the corners.

Fortunately, the threading on the skewer happened to be none other than my favorite thread: #10-32!! (also known as M5-.8 for those in communist countries) The reason I like it so much is because it's the only screw thread which is compatible for both American and metric, and it's a very versatile size used extensively on bicycles and exclusively on 19" amp racks and I believe also server racks.

|

| Still haven't built that hex die adapter! |

Then reassembling the hub taking care not to lose any of the ball bearings.

Now both wheels will fit more or less the same dropout spacing. Success!

Part 1 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.