Everywhere I go where there is a milling machine, there is always a set of strap clamps and T-slot nuts nearby. I didn't realize the importance of this until I actually wanted to clamp something that wouldn't fit in the vise. Basically, without strap clamps, you're missing out on 90% of clamping potential!

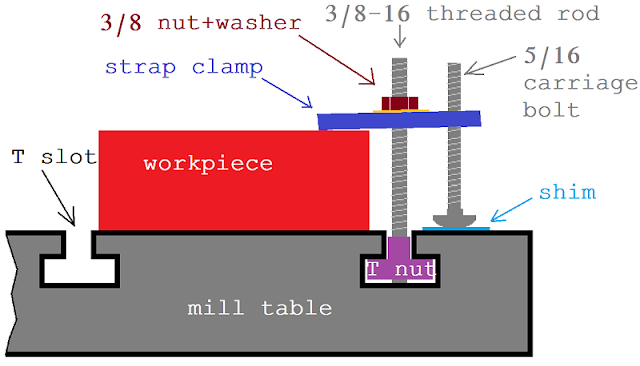

A strap clamp works by securing a clamp with a threaded rod to a T shaped nut in the corresponding shaped slot in the machine table. The back support for the clamp is usually provided by a staircase shaped wedge and stair shaped cuts in the back of the clamp, but that's unnecessarily complicated to make for my application. Instead, I decided to just tap a 5/16" hole in the back of the clamp and use carriage bolts to adjust the height range. The shim is so I don't mess up the table.