Since the last time I made a recycled notebook, I've devised a cunning and ingenious fixture to make them easier. I also got some brass shim stock and a bunch of colored printer paper from a rummage sale to make some with. For covers, this time I decided to try using a record sleeve and a recycled concert advertisement, both of which are stiffer than paper, and more waterproof than cardboard, and not too thick.

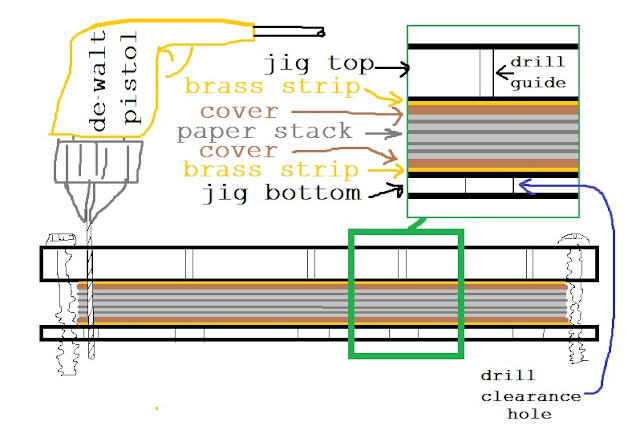

A closer look at the jig.

Here's how it works, basically it's like making a sandwich. Once all the layers are in the correct position, the screws on the jig are tightened, and the holes drilled. Not shown in the diagram is the tape I used to hold the brass strips to

the jig pieces so they wouldn't move around while positioning the other

layers.

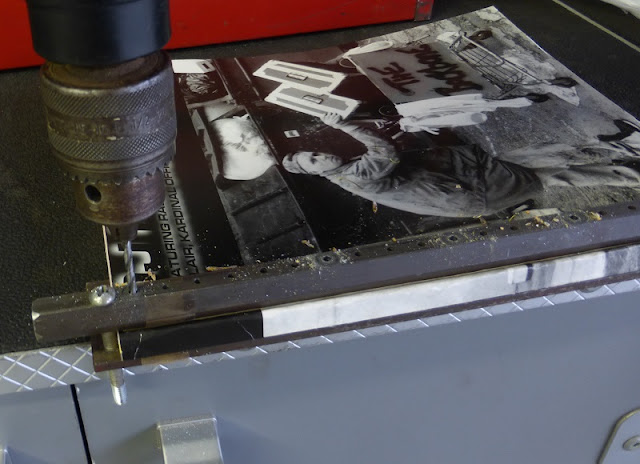

The jig with all the layers in position.

Drilling the holes. This jig ensures there would be no mismatch between any of the layers. Unlike last time when I used the Whitney punch, I couldn't fit all the paper in it at once, so the notebook ended up warped a little bit, not the case this time.

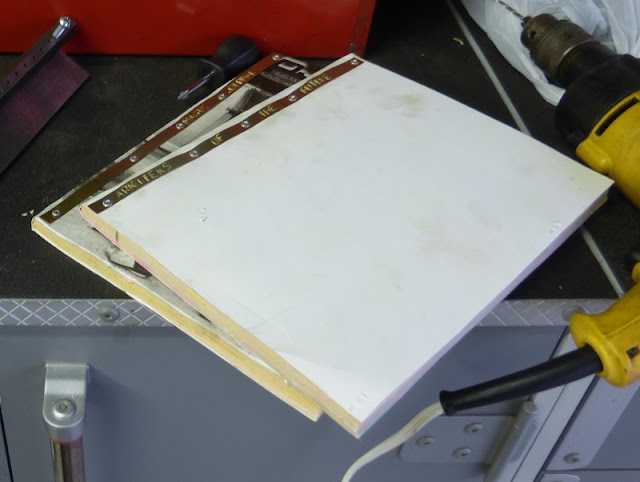

Then, the jig is loosened, moved over about an inch, and tightened again, but only clamping the paper and covers while the pop rivets are added to the binding strips.

I figured the brass binding would be more luxurious than aluminum since these notebooks were Christmas presents for some friends. I also got some letter stamps to customize them too. However, I didn't realize that letter punching the brass would bend the metal enough that the holes I punched wouldn't line up, so I had to punch them a size larger to correct this.

Score 2 for notebooks that don't have the pages falling out before you're done using them.

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.