I used a method I learned in sculpture class to trace the contours onto a piece of clay, and then remove material as the individual depths are cut.

|

| So ruff so tuff |

The finished and baked pattern.

|

| There is no spoon |

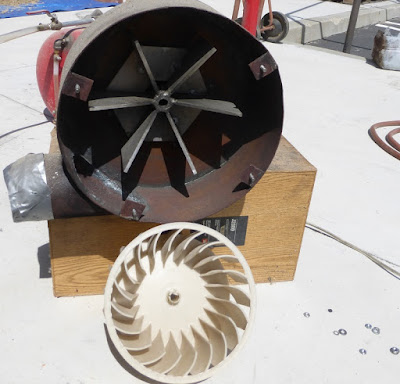

I got a new rotor for my blower from a clothes drier. This one has more fins, is lighter and plasticer.

Both rotors had half inch shaft holes, I had to file out the plastic on since it had a halfcircle type shape in it instead of a circular hole. I held it on with a hose clamp. Presumably, the blower should put out more air now, but at lower pressure. Not sure if it will help or not, but might as well try since I was having concerns with the other rotor of the motor overheating.

The melt went successfully. I had a bit of trouble lighting it since the oil was old, and pretty thick to begin with. I don't think my smoke signals were intercepted fortunately. I filled the crucible almost to the top, and almost dropped it a few times when pouring since my arm wasn't strong enough to lift it. I was expecting to need a lot of metal for the soap dish and 3 masks, but ended up only using half of what I melted, the rest going to ingots both in the usual tray, an aebleskiver pan, and a cast iron cookie pan shaped like sea creatures. Oh yeah, I started the furnace with the crucible filled with scrap aluminum lathe turnings. As the people tried telling me, they all turned into a mush of oxidized aluminum once the furnace got hot, yielding almost no usable metal. It was worth a shot. The sound of pouring metal into the soap dish mold was righteous, hearing and seeing it fill completely for the first time was very good. What are we on? the 4th or 5th attempt?

When pouring the masks, I spilled some aluminum on the cement, which they also told me not to do. Fortunately, it didn't cause a moisture explosion. Just made some aluminum pancakes. On the left is one of my new flasks I've been working on made of aluminum since the wood ones keep lighting on fire.

More ingots. I noticed a large air bubble in the ingots because I didn't clean out the tray before pouring. It was full of dust and rust.

We got the lobster and starfish ingots out the cookie pan. The manta ray got stuck because of aluminum poured through a hole in the pan by accident and solidified on both sides.

The Aku-Aku masks turned out fantastic!

|

| OOGUM BOOGUM!!! |

Then attempting to use the ejector pins which had been previously bent.

Then some chiseling

More chiseling

Pry barring

and even more chiseling

(30 minutes later)

And finally...

THE EXCALIBUR IS FREE FROM THE STONE!!!

|

| So shiny! |

All prophecies answered, and the case is closed. Alright, no more casting, we're done. (I say that after every casting session) People ask me why I do this, why do I work so hard just to make this stuff. I says Gangster rap made me do it. Why else would I keep putting rap references in my posts?

So, lessons learned:

- Don't go near the water if you can't swim the tide (or in this case, don't go near the foundry if you can't stand the heat)

- Go to community college so you can build cool stuff

- Don't make a soap dish out of metal

- Lift, bro

- Looking into the top of a furnace can cause dreadlocks

- Playing with fire is fun

- Make your ejector pins out of tool steel

- Plants can melt metal

- Leave diecasting to the diecasters

- I chiseled it

- The best soap is made from humans

Mold started spring 2013:

Mold completed January 2014:

February 2014:

March 2014:

December 2014:

February 2015:

March 2016:

See Aku Aku's completion

Proceed to episode 13 - New Crucible and Melting Brass

Back to episode 11 - Ankh

Back to foundry page

wow, so cool can make foundry of Aku-Aku.. (y)

ReplyDeleteReally good, keep up the good work!

ReplyDelete