|

| A plastic sink handle? This is heresy, blasphemy, polygamy!!! |

For a while we had just slipped a piece of stainless tubing over the rectangle as a temporary solution, but it was very loose and annoying. Still better than trying to open the valve with your fingers.

I decided to make a new handle by starting with some ¾" stainless round stock, boring a hole to fit over the rectangle, drilling and tapping a set screw hole, and welding a handle. The scrap piece of tubing for the new handle was conveniently capped on one end, so I didn't have to make an end piece, or risk having it look ugly being open on the end.

|

| The Pythagorean theorem comes to the rescue again. |

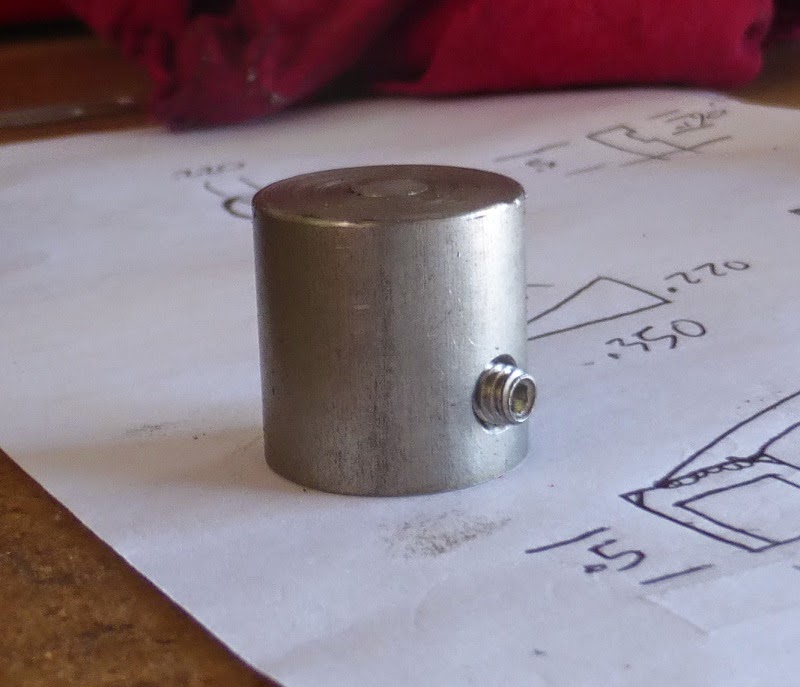

After parting it off, drilling the hole to be tapped for a #8-32 set screw.

Tapping the hole.

Here is the bottom part of the handle completed.

Then the handle part was welded on. Finally a good use for that bag of stainless welding rod that came with my welder that's been sitting around. I made sure to not weld all the way around because welding air-tight containers is a taboo, and also not necessary in this situation.

All done. This new handle is ∞ times better than that plastic crap. Rock Steady.

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.