I would've modified my old gravity fed tank, but I had trashed it in a rage of fury after the first success.

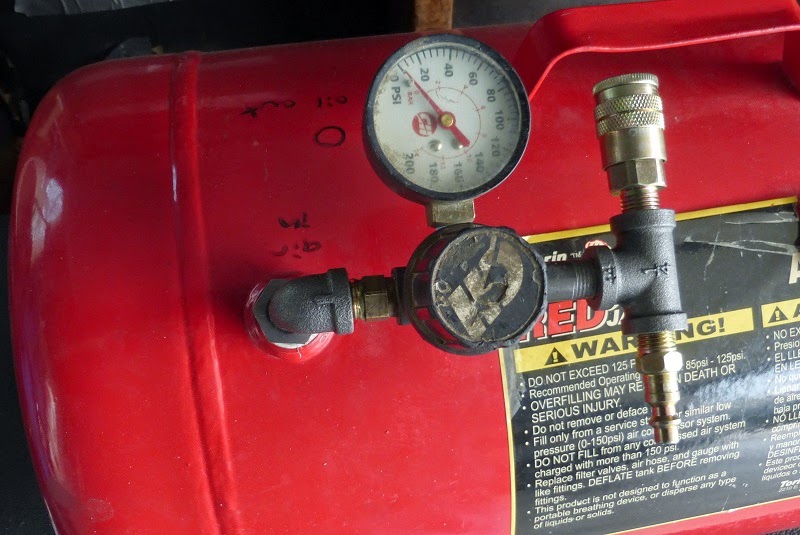

I went ahead and bought an 11 gallon air tank to modify to hold oil.

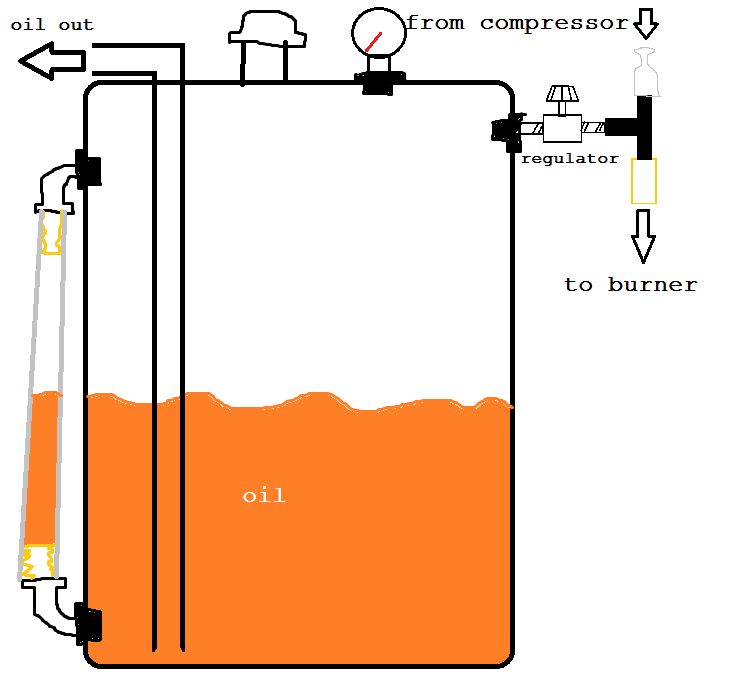

The basic design would be like this. I went with the idea of pressurizing the tank with compressed air through a regulator.

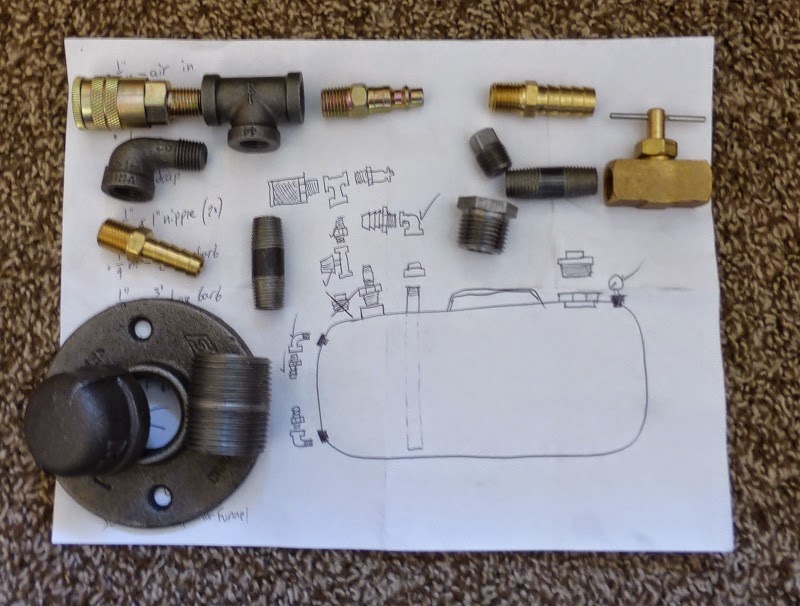

Here are some pipe fittings for the conversion.

With this configuration, I could plug an air hose from the compressor, and one through to the burner.

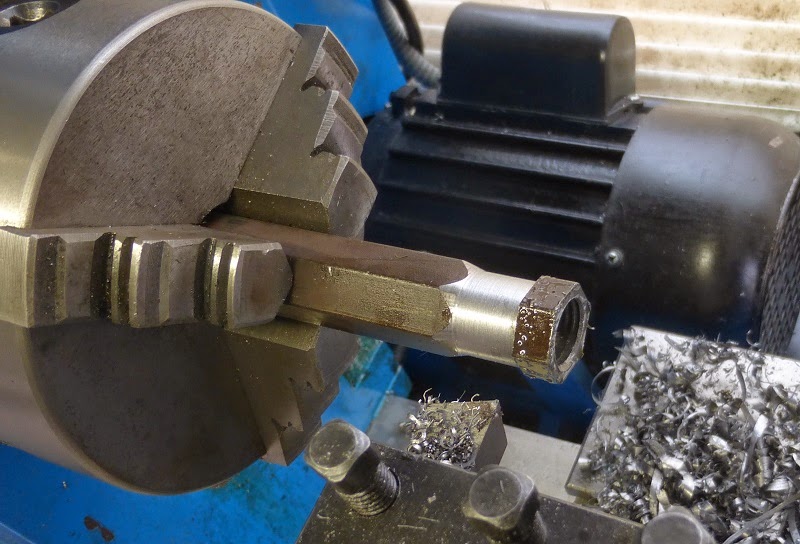

As for all the other stuff that would be attached to the tank, I made some ¼" pipe bushings to be welded onto the tank. I used hex stock because pipe tapping in the lathe generates so much torque that round stock would slip in the chuck jaws.

|

| Extended tap handles: very necessary |

Here are three bushings on the left, and the oil outlet piece on the right all ready to be welded onto the tank.

Drilling the holes in the tank. The oil inlet hole was the biggest as it is for a 1" piece of pipe. I had to use a hole saw to cut this one.

Then with all the bushings welded on.

Here it is all set up. Notice the tube on the left side, this shows how much oil is in the tank, which appears a little over half full in the picture. I made it by threading some street elbows into the bushings and then some hose barbs. Street elbows are really handy.

CONTINUE TO PART 9 -- TESTING EVERYTHING AND PRESSURE TANK DISASTER

BACK TO PART 7 -- Trying out the new burner

BACK TO THE FOUNDRY MAIN PAGE

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.